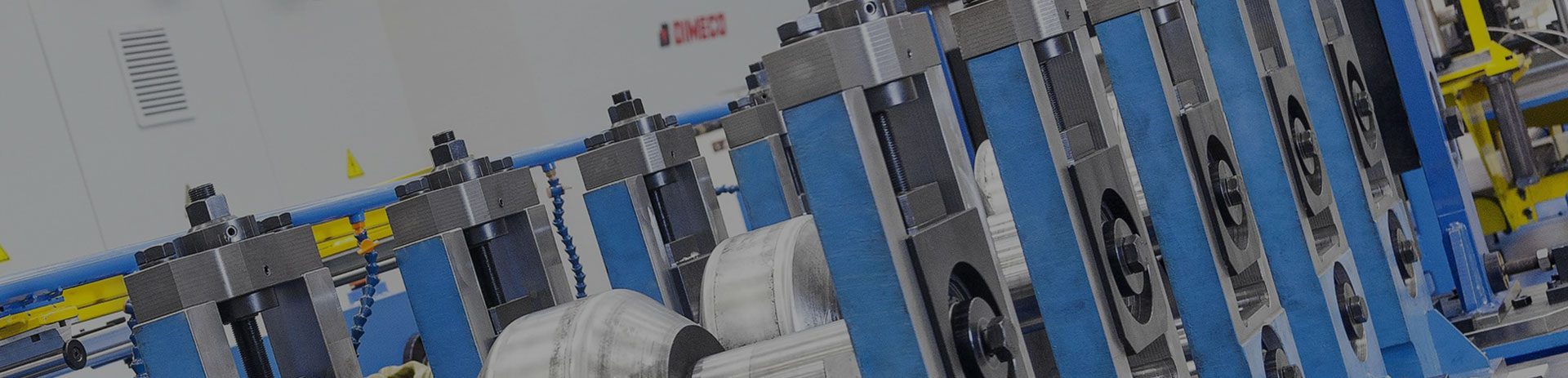

The rock wool production line is a set of equipment used to produce rock wool panels. Rock wool panels are fiber materials made from molten natural rock ores. They have excellent thermal insulation properties and are widely used in construction, refrigeration, decoration, and other fields. After years of research and development and improvement, the rock wool production line has become a set of highly efficient and highly automated modern equipment. This article will introduce the main equipment of the rock wool production line.

Smelting Section

The smelting section consists of a furnace (cupola or gas pool furnace), a four-roll centrifuge, a loader, etc.

The cupola is equipment used to melt rocks (slag). It has a cooling water circulation system on the furnace body to ensure the safety of the cupola. It is equipped with a hot air system that preheats by its own furnace temperature, making the equipment energy-efficient. It adopts a single-row multiple air hole structure and is equipped with an air volume control valve, making it easy to operate.

The pool furnace in the rock wool production line is built with refractory materials. Natural gas is sprayed into the pool to melt the raw materials by a spray gun.

The four-roll rock wool centrifuge is the main equipment for producing rock wool and slag wool. The four-roll centrifuge produced by our factory is a split type. The position of the rollers can be adjusted, making it reliable in operation, highly efficient, good in fiber quality, and easy to maintain.

Rock Wool Production Line Cotton Collecting Box Equipment

The cotton collecting box equipment of the rock wool production lines adopts a vertical cotton collecting function. The melting rock flows are spun into fibers by the centrifugal spinning machine and blown into the cotton collector. The negative pressure wind draws the fibers onto the mesh belt to form the original felt. The mesh belt transports the original felt to the pendulum distributor for swinging and distributing the cotton. The thickness of the cotton layer after swinging is uniform, significantly improving the quality of the products.

Panel Making Section

The panel making section consists of a cotton distributor, a curing forge, a cooling cutting machine, main power, a hot air furnace, etc.

Curing Forge

The curing forge is the equipment for forming the products. The felt after swinging and distributing the cotton is transported by the cotton distributor to the curing forge. It runs forward between the upper and lower chain belts. The hot air furnace blows hot air into the felt in the curing forge to cure and shape it.

Cutting Machine

The cutting machine's function is to cut the cured products. First, it performs longitudinal cutting, and then transverse cutting. Since the emergence of the insulation material market, it has always been bustling and never lacks new insulation materials. Whether it is foam glass or rock wool, they are regulars in the insulation engineering field.

JINGGONG is engaged in the production of large-scale rock wool production line equipment. This is equipment specially used for the production of rock wool products. High-quality completion of rock wool products' production relies on the rock wool production line, making it very popular in the market.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China