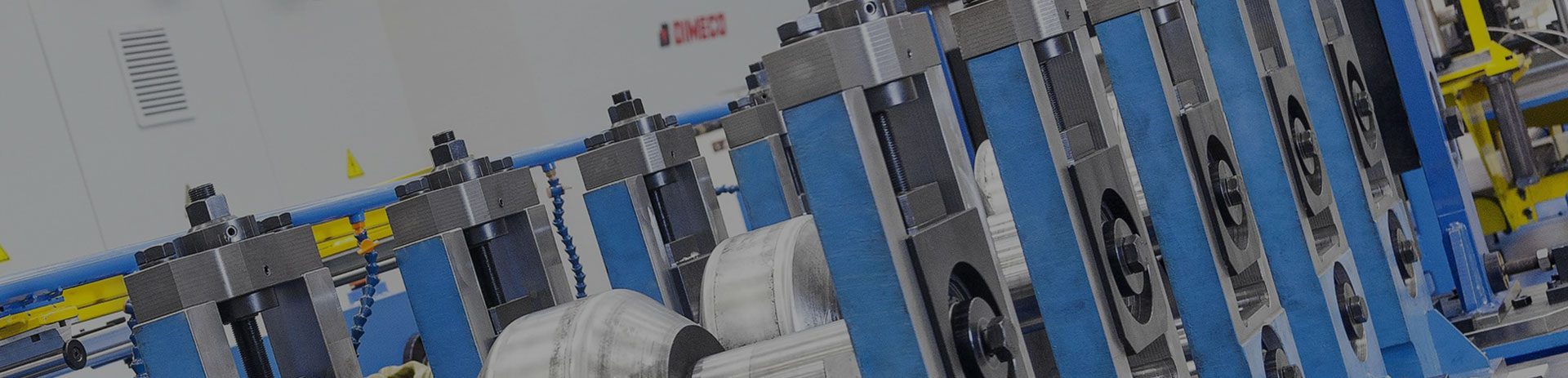

How to Reduce the Failure of the Roll Forming Machine?

After getting the equipment, many people immediately started endless production. But in the process of daily use, it is necessary to clean the dust on the equipment, inspect and maintain the parts, and keep the parts properly, so as to truly eliminate the failure of the roll forming machine.

The following are some effective maintenance tips:

Ⅰ. Dust removal.

After a long-term operation, a large amount of dust will accumulate inside and outside the roll forming machine, which needs to be cleaned. Besides, the remaining materials should be cleaned up after shutdown and coated with anti-rust oil to prevent long-term rusting of the equipment.

Ⅱ. Periodic inspection.

Check all parts of the molding machine regularly, about 1-2 times per month. The main inspection includes worm gear-worm-bearing-pressure wheel-crankshaft-upper and lower guide rails, mainly depending on whether there is wear between the parts. If there is, roll forming machine factory should carry out corresponding lubrication work.

Ⅲ. Die maintenance.

If the roll forming machine does not operate for a long time, the mold must be removed and placed in a tin box with a lid to keep it clean. If the situation permits, customize the tin box as much as possible. Packing in one box of each specification can avoid the wrong installation and help grasp the damage.

Ⅳ. Tidy working environment.

Roll forming machines have higher requirements for the working environment, especially for the tableting equipment of medical tablets and edible tablets. Equipment management personnel should clean it frequently to prevent dust from entering the molding machine and contaminating the tablet.

Although the performance of the roll forming machine is good, the management personnel still need to carry out reasonable maintenance on it, so as to increase the working efficiency while extending the service life.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China