Maintenance of Rockwool Sandwich Panel Production Line

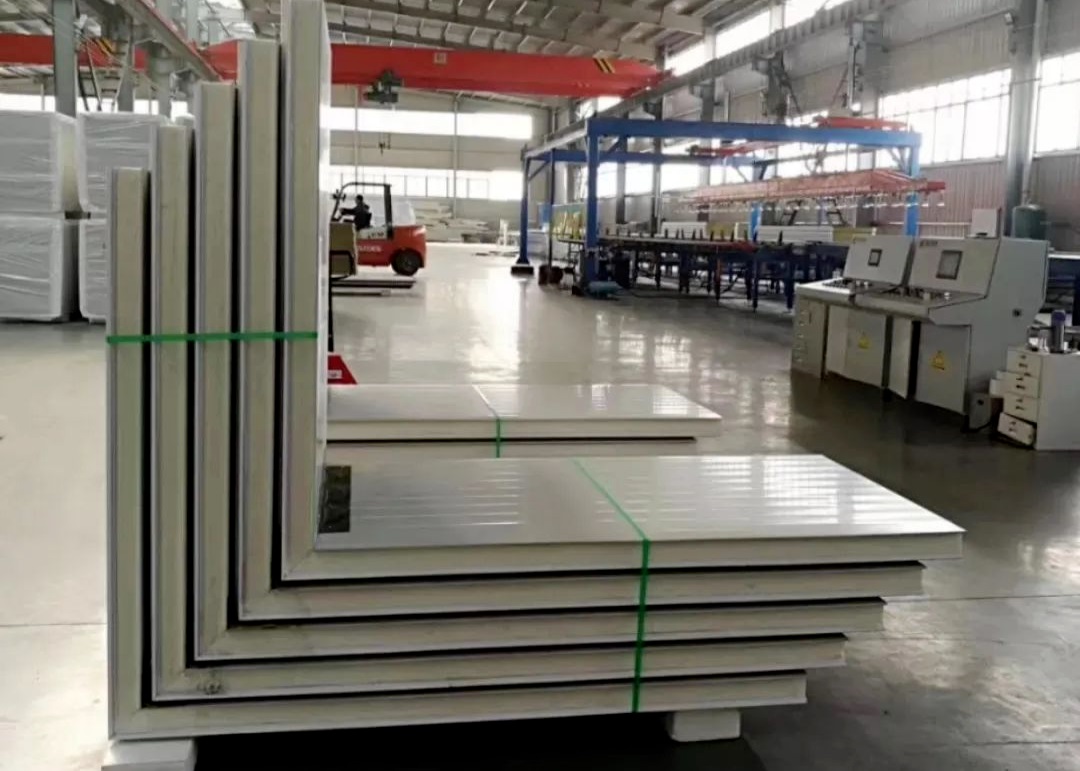

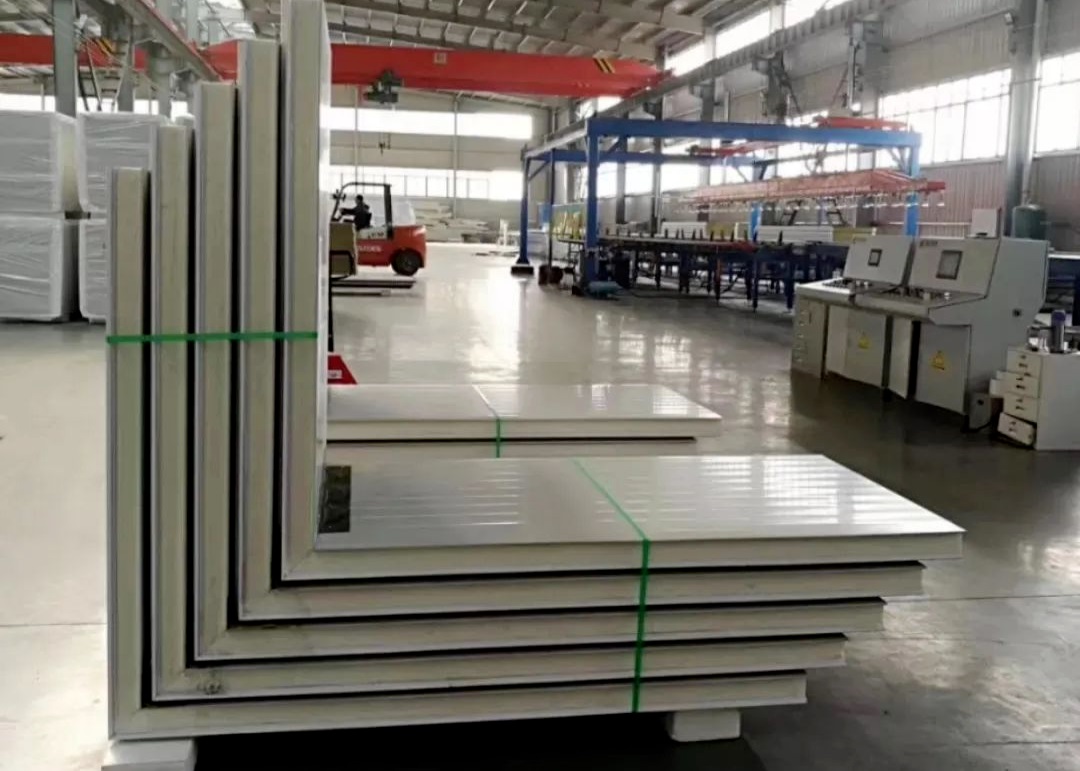

In the field of building material production, rock wool sandwich panels have become a popular choice in the modern construction industry due to their excellent thermal insulation, fire resistance, and sound insulation properties. A stable and efficient rockwool sandwich panel production line is the core guarantee for ensuring product quality and output. Scientific and reasonable maintenance work can not only extend the service life of the equipment on the rockwool sandwich panel production line but also reduce failure rates and improve production efficiency.

Keeping the equipment clean is crucial

During production, a large amount of rock wool debris, dust and impurities will adhere to the surface and inside of the equipment. If not cleaned in time, these impurities may enter key parts of the equipment, such as transmission components and electrical systems, leading to aggravated wear of parts and short circuits in circuits. For parts that directly contact materials, such as conveyor rollers, cutting tools, and forming molds, more detailed cleaning is required to avoid material residues affecting product quality.

Strictly enforce component inspection systems

Before starting and after shutting down each day, it is necessary to check the connection status of each component of the equipment. Screws, nuts, and other fasteners may loosen due to vibration during operation. If they fall off, it may cause abnormal equipment operation at best, and safety accidents at worst. At the same time, closely monitor the operating status of the conveyor belt to check for wear or deviation. If the conveyor belt is found to be severely worn, its position should be adjusted or a new conveyor belt should be replaced in time to ensure the stability and accuracy of material transportation.

Daily maintenance is the fundamental work to ensure the stable operation of the rockwool sandwich panel production line, running through every link of the production process.

Maintain good lubrication of equipment

During operation, transmission components, bearings, gears, etc., will generate friction. Good lubrication can significantly reduce friction, reduce part wear, and extend the service life of the equipment. According to the requirements of the equipment manual, set a reasonable lubrication cycle, for example, every 200-300 hours of operation, add or replace lubricating grease or lubricating oil for the corresponding parts. When adding lubricating oil, control the amount of oil to avoid too much or too little, and pay attention to the requirements of different parts for the type of lubricating oil to ensure the use of the correct lubricant.

Regularly inspect the electrical system

As the "nerve center" of the rockwool sandwich panel production line, the stability of the electrical system directly affects the normal operation of the equipment. A comprehensive inspection by a professional electrician is required every month. Inspection items include checking for aging or damage to wires, the working status of electrical components (such as contactors, relays, inverters, etc.), and the reliability of grounding. Wires that are aging or damaged must be replaced promptly, and for abnormal electrical components, they need to be repaired or replaced to ensure the electrical system runs safely and reliably. In addition, dust should be regularly removed from electrical control cabinets to prevent dust accumulation from affecting the heat dissipation and performance of electrical components.

Regular maintenance is a systematic, in-depth maintenance of the rockwool sandwich panel production line, which can effectively reduce the wear and tear caused by long-term operation of the equipment.

In summary, the maintenance of the rockwool sandwich panel production line is a systematic and meticulous task. Only by implementing various maintenance measures and establishing a scientific and comprehensive maintenance system can the rockwool sandwich panel production line be ensured to run stably and efficiently in the long term, creating greater economic benefits and competitive advantages for enterprises.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China