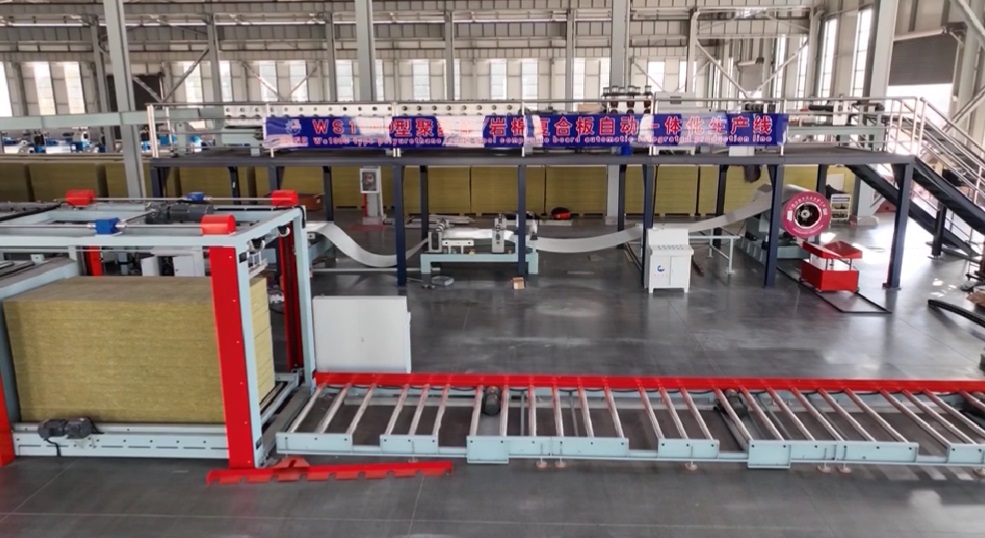

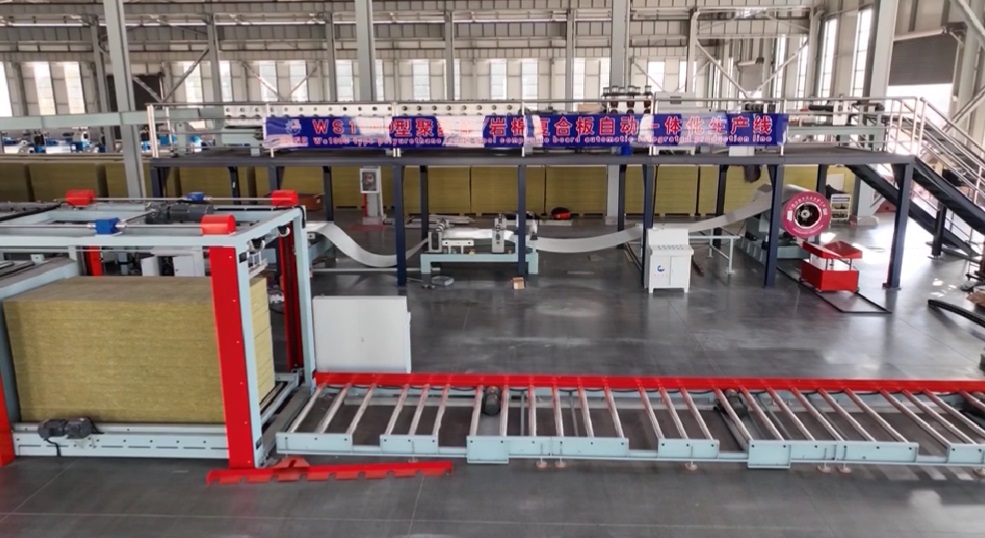

The Core Role and Process Analysis of An Automated Rockwool Production Line

Currently, the limitations of traditional rock wool production methods in terms of efficiency and quality control are becoming increasingly evident. Automated rockwool production lines, with their intelligent and precise production advantages, are becoming the core engine driving industry innovation. These lines not only significantly enhance production efficiency and product stability but also reshape the entire rock wool production process through advanced process technologies. This article explores the core role and principles of automated rockwool production lines.

Significantly Improving Production Efficiency

Automated rockwool production lines use highly integrated control systems to seamlessly link all stages such as raw material delivery, melting, fiberizing, forming, and cutting. In traditional manual operations, there are time gaps between stages and susceptibility to human error. In contrast, automated production lines use sensors and PLC control systems to monitor and automatically adjust production parameters in real time, achieving 24-hour continuous high-efficiency operation.

Ensuring Product Quality Stability

Consistency in product quality is key in the rock wool market. Automated production lines, leveraging precise parameter control and automated inspection equipment, can ensure that rock wool products maintain high stability in core metrics such as density, thickness, and compressive strength.

Reducing Labor Costs and Production Risks

Traditional rock wool production relies heavily on manual operations, leading to high labor costs and significant safety risks in high-temperature melting and high-speed equipment operation. Automated rockwool production lines replace manual tasks with robotic arms and automated conveyors, reducing labor input by over 60% and effectively lowering operating costs. Additionally, protective systems and intelligent warning features in automated equipment can monitor equipment status and production environments in real time, quickly identifying and addressing potential safety hazards, thus providing strong guarantees for safe production.

Process of Automated Rockwool Production Lines

Raw Material Preprocessing

The raw material preprocessing stage in an automated rockwool production line achieves full-process intelligent control. Basalt, dolomite, and other raw materials are first conveyed through an automated system into crushing equipment, where they are precisely crushed to the appropriate size. During the batching phase, high-precision weighing sensors and an automated batching system work together to mix different raw materials evenly according to the formula ratio, laying the foundation for subsequent production.

High-Temperature Melting and Fiberizing

The mixed raw materials are fed into a high-temperature furnace via an automated feeding system. The furnace, equipped with an intelligent temperature control system, accurately maintains the temperature between 1400°C and 1600°C to ensure thorough melting of the raw materials. The molten material is introduced into a high-speed spinning machine through an automated flow duct; under the dual action of centrifugal force and high-speed airflow, it is stretched into fine rock wool fibers.

Collection and Forming

The rock wool fibers ejected from the spinning machine are collected onto a net belt under negative pressure, forming a uniform fiber mat. The automated collection system precisely controls the thickness and density of the fiber mat by adjusting the belt speed and negative pressure. The fiber mat is then fed into automated forming equipment, where it is pressed and sprayed with an adhesive to form rock wool boards or rolls with specific strength. During forming, the automated control system continuously monitors the pressure, temperature, and adhesive spraying amount to ensure stable product forming quality.

Curing and Cutting

The formed rock wool products are sent into an automated curing furnace, where precise control of the temperature curve and dwell time allows the adhesive to fully cure, enhancing the product's strength and stability. After curing, the automated cutting system precisely cuts the rock wool products to the specified dimensions.

Packaging and Storage

The cut rock wool products are conveyed to the packaging stage through an automated line, where robotic arms perform bagging, sealing, and labeling operations. The packaged products are automatically transported by AGV carts to an intelligent storage system, which stores them optimally based on product specifications and batch information. The entire packaging and storage process is automated, ensuring efficient and orderly intelligent management.

Advantages of JINGGONG Rockwool Production Line

High production efficiency, meeting market demand.

High product quality, uniform density, stable quality, excellent insulation, and fire resistance.

Low production costs, high degree of automation, effectively reducing labor costs and material waste.

With its core advantages in production efficiency, quality control, and cost management, as well as advanced intelligent process technologies, the automated rockwool production line has become a key force in driving the upgrade of the rock wool industry. In the future, automated rockwool production lines will inject new momentum into the sustainable development of the green building materials industry.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China