Rock wool, as an environmentally friendly and efficient building material, has been widely used in construction, industry, transportation, and other fields. Modern rockwool production lines not only significantly improve production efficiency but also further optimize product quality. This article will provide a detailed introduction to the functions of rockwool production lines and their main application fields.

Main Functions of Rockwool Production Line

In the production process of rock wool, adopting a rockwool production line can bring multiple benefits. Firstly, the rockwool production line uses automated production, making work more efficient and less labor-intensive, effectively improving the production efficiency of rock wool. Secondly, the rockwool production line can ensure the stability and consistency of production quality, especially in terms of controlling product density, thickness, and other aspects more accurately. The rockwool production line can also save raw materials usage, reducing the material wastage rate to a very low level, thereby achieving cost savings. These advantages not only improve production efficiency and product quality but also save expenses for enterprises, increase competitiveness, and better serve consumers.

Rock Wool as a Green and Environmentally Friendly Building Material

Rock wool, also known as mineral wool, is a material made from basalt, diamond, rock wool, and other raw materials, which has special functions like thermal insulation, soundproofing, fire resistance, and corrosion resistance. Rock wool, as a green and environmentally friendly building material, is widely used in building fire prevention, soundproofing, and thermal insulation. In the production process of rock wool, using a rockwool production line not only substantially improves production work efficiency and consistency of production quality but also saves raw materials, reduces production costs for enterprises, increases market competitiveness, and contributes more to sustainable development.

Main Applications of Rockwool Production Line

Materials prepared by rockwool production lines are widely used in construction, refrigeration, soundproofing, and fire prevention fields.

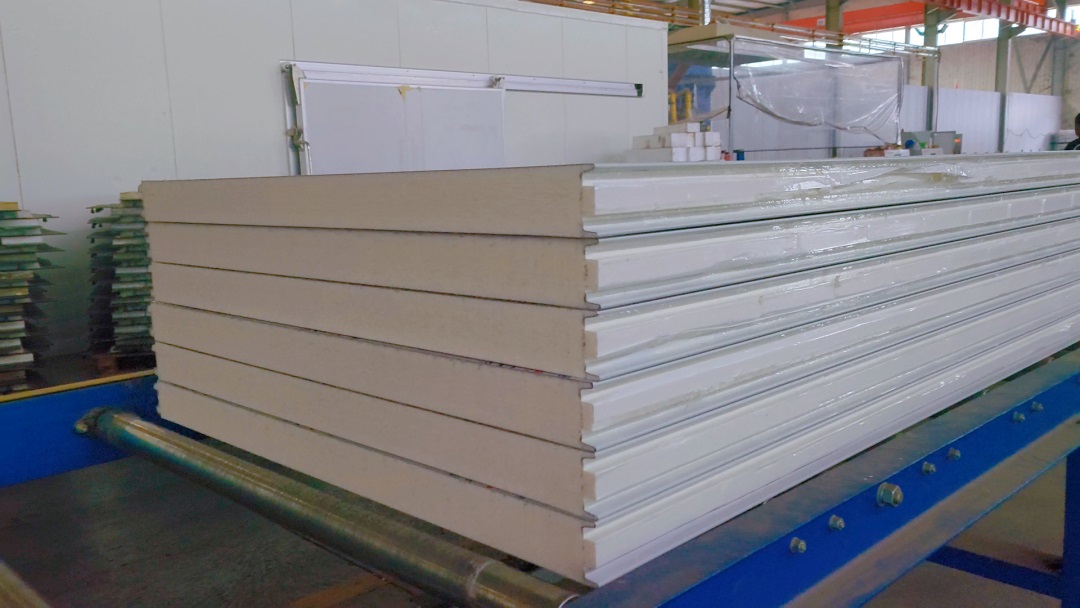

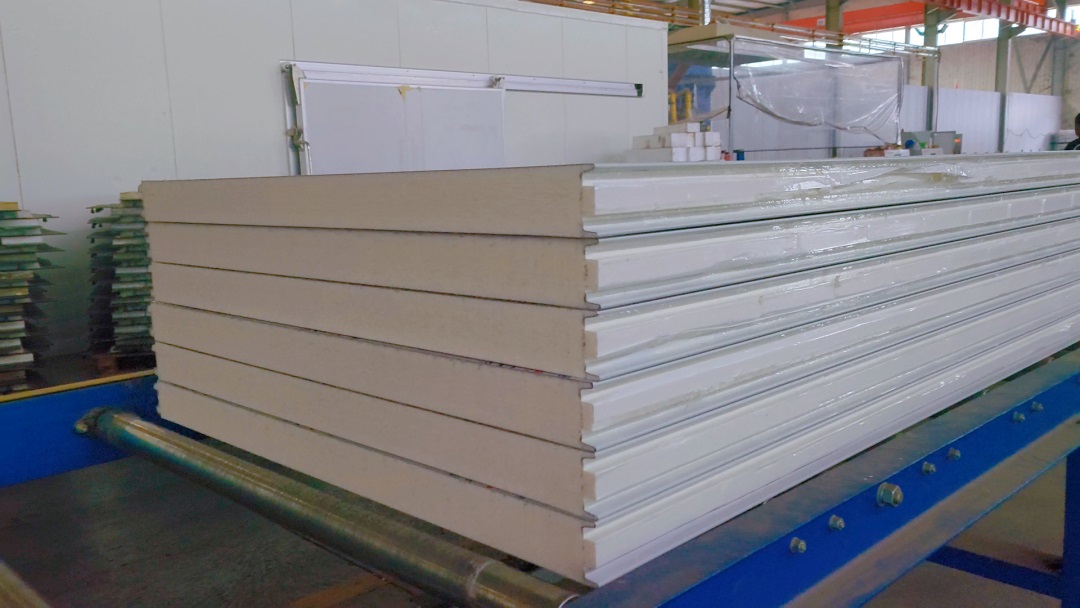

Rock wool boards and rock wool pipes are commonly used insulation materials in buildings. Rock wool boards can be cut into various shapes and assembled according to different building structures to achieve thermal insulation, heat preservation, and fire prevention purposes. Rock wool pipes are used for thermal insulation in cable pipelines, water pipes, and other pipelines. Due to their green and environmentally friendly characteristics and ease of processing, rock wool insulation materials have become one of the environmentally friendly energy-saving materials used in construction.

Rock wool refrigeration equipment is commonly used as a refrigeration material in industrial refrigeration and freezing equipment. Rock wool refrigeration equipment is convenient to use, has strong insulation performance, and can achieve a cooling temperature of up to -200°C. Rock wool refrigeration equipment is widely used in supermarkets, cold storage, food production, and other fields, providing fire prevention, insulation, and cooling functions. With its insulation characteristics, rock wool is widely used in power stations, stations, television stations, and other places requiring soundproofing. Rock wool soundproofing materials can effectively reduce noise and improve indoor insulation and soundproofing effects. In addition to soundproofing, rock wool also has fire resistance capabilities. In the event of a fire, it can withstand high temperatures for more than four hours, providing reliable safety protection for buildings and industrial equipment.

Besides the construction and refrigeration fields, rock wool is also widely used in automotive components, such as engine covers, brake pads, exhaust pipes, etc. Rock wool not only provides significant noise reduction and vibration damping effects but also has good heat-resistant and fire-resistant properties. Rock wool is also widely used as a thermal protection material in solar power plants. As an insulation material, it can reduce heat loss and prevent solar panels' performance from declining due to temperature effects.

Rockwool Production Line Provides a Healthy User Experience

As consumers, product quality and user experience are the main concerns. The application of rockwool production lines ensures more uniform density distribution and smaller thickness deviations in rock wool products, not only ensuring the stability and consistency of products but also improving the fire resistance, soundproofing, and thermal insulation performance of products. Therefore, whether in decoration, construction, transportation, or in environmental protection, health, and living fields, the application of rockwool production lines will undoubtedly bring better product performance and provide users with a healthier user experience.

The Advantages of JINGGONG Rockwool Production Line

High production efficiency, meeting market demands.

Good product quality, uniform density, stable quality, strong insulation, and fire resistance.

Low production cost, high level of automation, effectively reducing labor costs, and minimizing raw material waste.

In summary, rock wool materials produced by rockwool production lines have become indispensable materials in modern construction, refrigeration, soundproofing, and fire prevention fields. With continuous iteration and updates, the benefits brought by rockwool production lines will become more evident.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China