The Key Role of Rockwool Production Line in Continuous Hot-Dip Galvanizing Line of Strip Steel

The Synergy Between Continuous Hot-Dip Galvanizing Process of Strip Steel and Rockwool Production Line

The continuous hot-dip galvanizing production line for strip steel is an essential piece of equipment in the modern metal processing industry. Its primary function is to enhance the corrosion resistance of materials by coating the surface of strip steel with a zinc layer. The entire process requires strict temperature control, and that's precisely where the high-quality insulation materials produced by the rockwool production line play an indispensable role. Rockwool, an inorganic fiber material made by melting and centrifuging basalt and other mineral raw materials at high temperatures, provides excellent thermal insulation, which ensures the stable operation of the hot-dip galvanizing process.

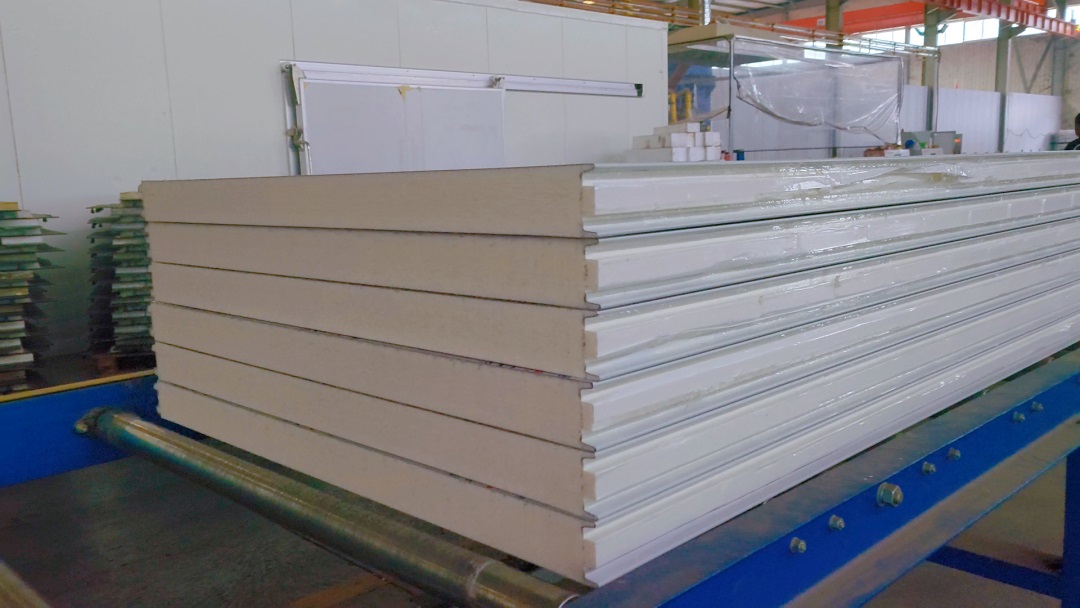

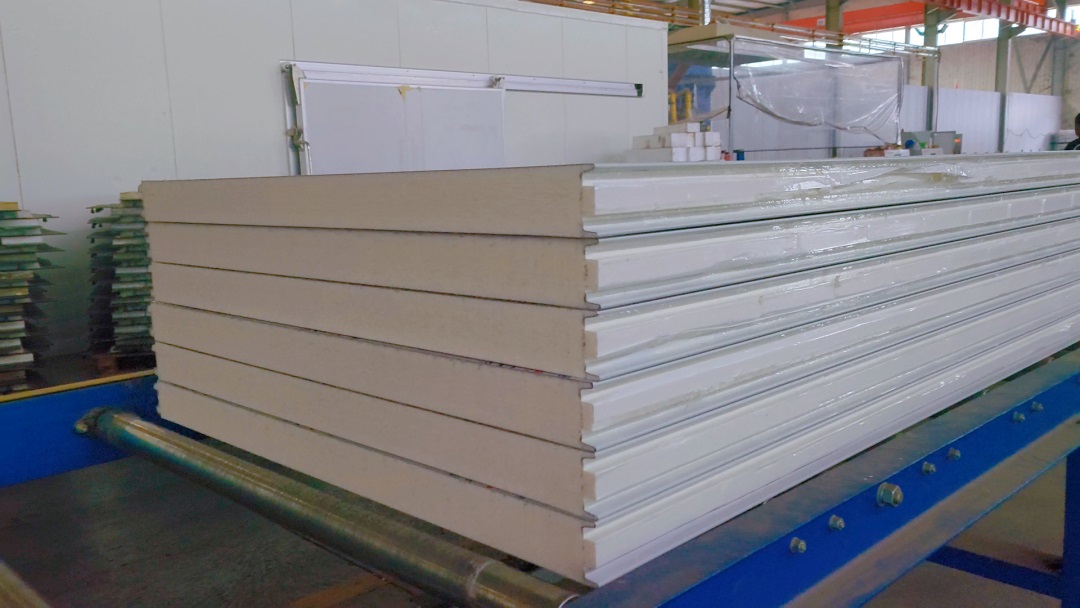

Unique Performance Advantages of Rockwool Production Line Products

The rockwool production line, through a precisely controlled production process, manufactures rockwool products with excellent characteristics. This material not only has a very low thermal conductivity, effectively preventing heat loss, but also demonstrates outstanding high-temperature resistance, being able to withstand working temperatures over 600℃ for extended periods. The rockwool production line places particular emphasis on controlling product density, ensuring that the finished product maintains excellent insulation performance while having adequate mechanical strength. These features precisely meet the stringent requirements of the continuous hot-dip galvanizing line for insulation materials.

Core Application Value of Rockwool in Hot-Dip Galvanizing Process

In the actual operation of the continuous hot-dip galvanizing production line for strip steel, insulation materials provided by the rockwool production line are mainly used in several key areas. First is the insulation system of the galvanizing pot; by laying a rockwool insulation layer, heat loss of the zinc liquid can be significantly reduced, cutting energy consumption by about 20-30%. Next is the insulation of various heat treatment furnaces; the stable performance of rockwool ensures precise control of process temperatures. Additionally, in the insulation treatment of auxiliary systems like hot air ducts, rockwool performs excellently, and its fire resistance adds a critical layer of safety to the entire production line.

Continuous Improvement in Technological Innovation and Comprehensive Efficiency

With the continuous advancement of rockwool production line technology, new generations of rockwool products are bringing further optimization possibilities to the continuous hot-dip galvanizing process. The rockwool production line employs intelligent control technology, making product quality more stable and reliable. In practical applications, these high-performance rockwool materials not only significantly improve the energy efficiency of the hot-dip galvanizing production line but also indirectly enhance the quality consistency of galvanized products by maintaining stable process temperature ranges. Statistics show that the comprehensive operational efficiency of hot-dip galvanizing lines using high-quality rockwool insulation systems can be increased by more than 15%.

In conclusion, the continuous hot-dip galvanizing production line for strip steel provides corrosion-resistant and durable metal materials, with rockwool production lines playing a crucial role in this process. As a high-quality insulation material, rockwool can further enhance the corrosion resistance of metal materials. The extensive application of rockwool production lines has provided convenience for the continuous hot-dip galvanizing production line, promoting the development of modern industry.

CN

CN

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro

Call us on:

Call us on:  Email Us:

Email Us:  #1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China

#1809, Jianhu Rd, Keqiao, Shaoxing, Zhejiang, China